Design Standards

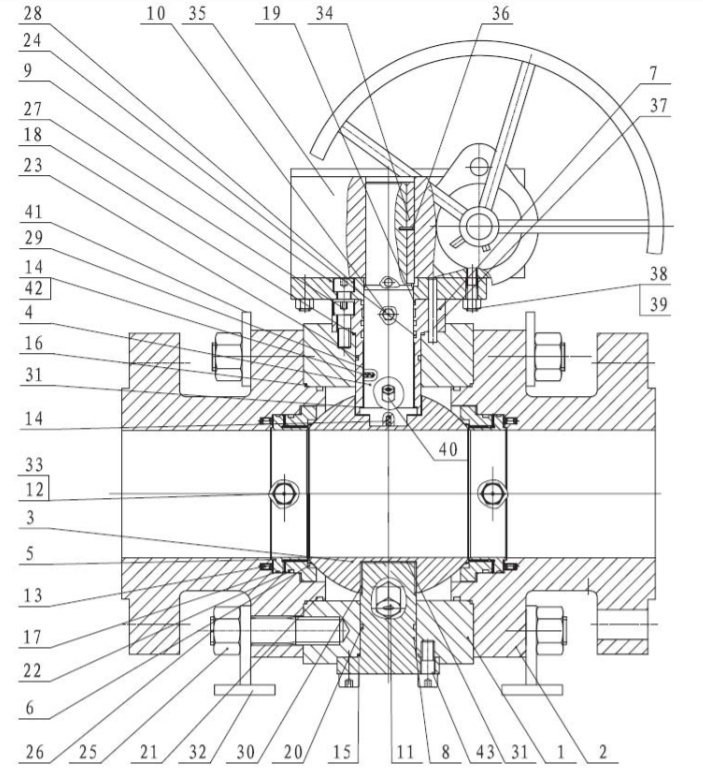

- Body joint integrity and fire safety is ensured by dual independent seals

- A tight tolerance overlapping metal to metal body joint ensures valve is capable of handling pipeline stress and misalignment.

- Standard forged body, bonnet and ball ensures high strength and higher integrity grain structure

- All trunnion ball valves are equipped with a locking device to API 608. For gear operated valves, this feature is included on the gear operator

- All trunnion ball valves are equipped with ISO 5211 actuator mounting flanges

- Standard trim in either full stainless steel (DBB only) or 3 mil high phosphorus electroless nickel plated for superior corrosion protection

- Blow out proof stem

- Stems and trunnions are manufactured separately from the ball and supported by a bearing and thrust washer to ensure low consistent torques

- All valves include emergency secondary stem sealant injection system

- Special wide seat insert design provides an increased life in difficult service conditions

- Seat ring sealing includes separate graphite seals for fire safe design and O-rings for tight sealing

Tagging is per the requirements of API 6D, MSS SP-25 and CSA Z245.15

Reference Standards

Design Standard:

API 608

API 6D

ISO 17292

CSA Z245.15

CSA B51

Face to Face:

ASME B16.10

Flange:

ASME B16.5

Marking:

MSS SP-25

Inspection:

API 598

Pressure & Temp.:

ASME B16.34

Quality:

MSS SP-55

Fire Safe Design:

ISO 10497

API 607

API 6FA

Sour:

NACE MR0175

ISO 15156

Pressure Testing:

API 6D

ISO 5208

Documentation: BS/EN 10204-3.1